Part I here: https://inchhighguy.wordpress.com/2024/04/19/bf-109g-comparison-build-hasegawa-fine-molds-tamiya-eduard-kits-part-i/

Scale Modeling and Military History

Part I here: https://inchhighguy.wordpress.com/2024/04/19/bf-109g-comparison-build-hasegawa-fine-molds-tamiya-eduard-kits-part-i/

A beautiful photograph of the new battleship USS Connecticut (BB-18) on her builder’s trials off the Maine coast, 1906. Connecticut carried twelve coal-fired Babcock & Wilcox boilers for a maximum speed of 18 knots, impressive for the time. Photographed by Enrique Muller.

This Henschel Hs 129 of 4.(Pz)/Sch.G. 1 with an impressive scoreboard was photographed in Russia during the Summer of 1943. Italeri kit, Excito decals.

Photographed by Don Gilman at Cavenaugh Flight Museum, Dallas

Part I here: https://inchhighguy.wordpress.com/2020/02/09/mig-21pf-walk-around/

Model Con 419 was held yesterday at the Quality Inn in Perrysburg, Ohio. The show was a collaboration between the IPMS Fremont KitBashers and the Toledo Plastic Modelers. This was the first show in the Toledo area since 2018, for those wondering 419 is the local telephone area code and the show was part of a series of events in the greater Toledo area. Being the first show in a while it was on the smaller side. Big Burel’s BBQ food truck was on hand. Everything wrapped up early, with many venders packing up around lunch time, and judging was completed by 3:00.

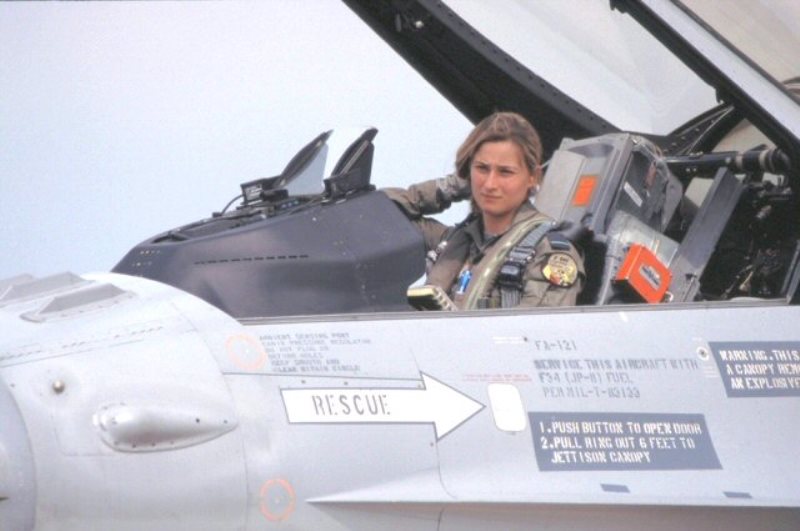

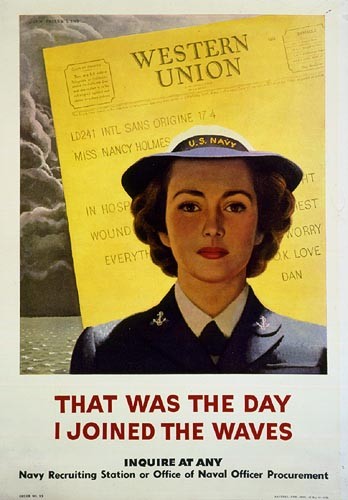

To see more Women Warriors, click on the tags below:

Part II here: https://inchhighguy.wordpress.com/2024/04/26/bf-109g-comparison-build-hasegawa-fine-molds-tamiya-eduard-kits-part-ii/

A U.S. Navy Sikorsky JRS-1 flying boat in the Yellow Wings scheme, this example was assigned to VJ-4. In the civilian market they were known as the S-43, most famously operated by Pan Am as “Baby Clippers”. The USAAC purchased five as the OA-8, the USN operated seventeen as the JRS-1. The type soldiered on into 1941, where at least one was present for the Pearl Harbor Raid and searched for the Japanese Fleet. A survivor is preserved in the Smithsonian Institution.

Scale models, where they come from, and people who make them

Scale diorama tips and ideas

Let's build, and build again even if you won't build everything you have bought

A futile fight against entropy or 'Every man should have a hobby'? Either way it is a blog on tabletop wargames, board games and megagames

World War II with Scale Models

Illustrating Stories, Painting Miniatures, Reviewing Realms.

This is my ad free non-profit blog of my research notes on military history since April 2018.

Moving with the tides of history

Building and improving scale models

WHENEVER ANY FORM OF GOVERNMENT BECOMES DESTRUCTIVE OF THESE ENDS (LIFE,LIBERTY,AND THE PURSUIT OF HAPPINESS) IT IS THE RIGHT OF THE PEOPLE TO ALTER OR ABOLISH IT, AND TO INSTITUTE A NEW GOVERNMENT― Thomas Jefferson

Let's build and build again

This WordPress.com site is Pacific War era information

Scale Modeling and Military History

The best in WWII aviation history

Scale Modeling and Military History

Relaxed kind of plastic scale modelling

Scale Modeling and Military History

Scale Modeling and Military History

Scale Modeling and Military History

Scale Modeling and Military History

Scale Modeling and Military History

Scale Modeling and Military History

Scale Modeling and Military History

A blog about Modeling and life in general